We manufacture a variety of custom pad shapes and sizes to fit your equipment. These include the most common standard square or rectangle pads for AAR switcher trucks and other standard rolling stock, U-bottom pads for Symmington round-bottom boxes, 3-section winged pads, and 2 section 1/3-2/3 divided pads for Crown Metal Products rolling stock. We also make special shapes such at T-shaped pads for Baldwin steam locomotive driving box cellars, three sided “star” pads for Brill trolley cars, and narrow pads for Chicago Transit Cars., and even tiny 3x3 pads for 15” gauge equipment.

In addition, we customize the designs to fit your needs. We make accommodations for oil pump feed pipes in cellars (photo with red circle in corner), and add restraint loops to prevent pad rolling on large mainline steam locomotive cellars (CP 2816, C&NW 1385). We are happy work with customers to design a system to meet these unique needs.

Materials and labor:

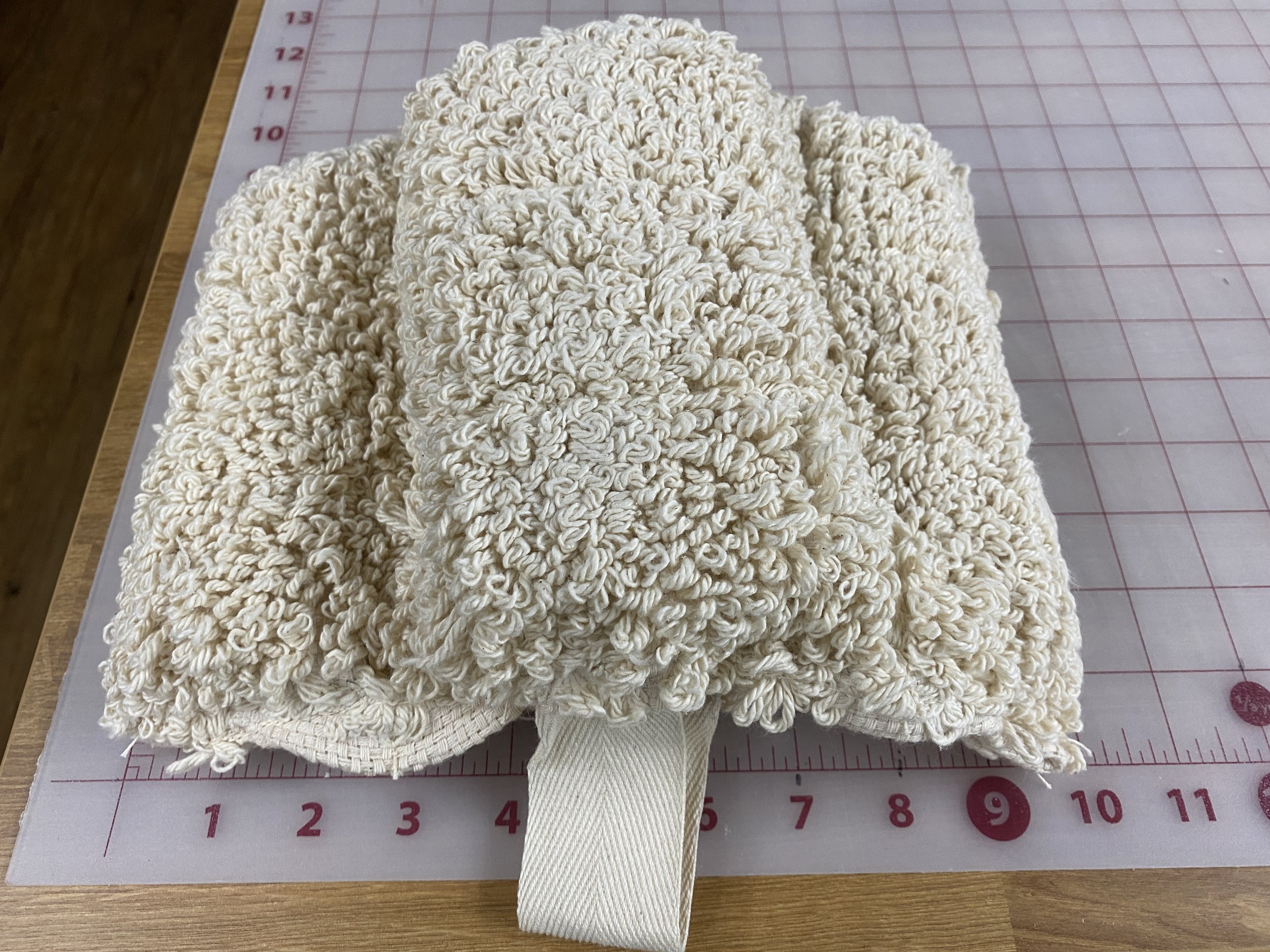

We chose natural undyed cotton for our pad covers due to its excellent surface chemisrty wicking oil with maco and mico capillary action*. Our in-house manufacturing of the cover material gives full control over loop density and manufacturing quality. Pad cores use spongy open cell polyurethane foam designed to hold up well in an oil environment and provide consistent contact with the axle. Larger pads also use natural cotton mop yarn wicks through the foam core to wick oil directly through the center. We source raw materials in the USA whenever possible to support jobs. Due to the narrow niche market, it’s not a full time job. Labor, chief cook and bottle washer are all me (Craig), with occasional help from my wife Katie if we receive a big order. Occasionally an orange cat wanders down and supervises production.

* Wool is known to offer slightly improved selectivity of oil adsorption over water, however the 8x price increase is not justifiable, especially considering that pads are consumables designed to be changed out. If you still desire a wool tufted pad (a few hundred dollars each), contact us and we can discuss tooling up for such a project. We’ve also considered cat fur fibers but the production rate is limited to the seasonal shedding of 2 short hair cats.

Commitment to price:

We build prices around materials and labor costs and we uphold our commitment to keep prices low so that organizations of all budget levels can afford to keep their equipment rolling. We continue to purchase specialized equipment that helps make the product more precisely and efficiently. This helps offset the increasing cost of raw materials which would otherwise force us to raise prices.